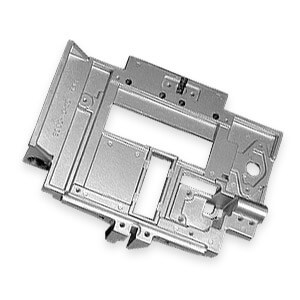

Learn why industries trust Precision aluminum casting for high-quality results

Wiki Article

The Importance of Aluminum Spreading in High-Quality Manufacturing Techniques

Aluminum spreading has become a cornerstone in premium production strategies. Its light-weight buildings and phenomenal strength make it a preferred choice for numerous markets. Manufacturers take advantage of its style flexibility and very little waste generation. As the demand for innovative materials expands, comprehending the nuances of light weight aluminum casting becomes crucial. This exploration discloses not just its benefits yet likewise the evolving modern technologies that shape its future in production. What lies in advance for this ingenious procedure?

The Advantages of Light Weight Aluminum Spreading

Different casting methods exist, light weight aluminum casting stands out due to its countless advantages. Among the main benefits is its light-weight nature, which considerably reduces transportation costs and energy consumption in applications. Light weight aluminum also displays excellent deterioration resistance, making it optimal for long-lasting parts in diverse atmospheres. The spreading process permits for intricate styles, allowing makers to produce complicated forms with high precision and very little waste. In addition, light weight aluminum has exceptional thermal and electric conductivity, making it ideal for a variety of commercial applications. The high strength-to-weight proportion enhances the structural stability of cast items, providing resilience without the added mass. Aluminum casting can be adjusted to numerous strategies, such as sand casting or die casting, which expands its applicability across industries. Generally, these benefits placement light weight aluminum casting as a preferred choice in contemporary production, adding to performance and sustainability.Trick Applications of Aluminum Casting

Aluminum spreading discovers substantial applications throughout numerous sectors as a result of its useful buildings. In the automobile industry, it is commonly utilized for producing engine blocks, transmission cases, and wheels, promoting lightweight styles that improve fuel effectiveness. The aerospace industry also gains from aluminum casting, where elements such as real estates and braces are generated to satisfy strict weight and strength needs.In addition, the electric market utilizes aluminum spreading for creating housings and heat sinks, which are vital for efficient thermal management in digital gadgets. aluminum casting. The building market utilizes light weight aluminum spreadings for architectural elements, home window structures, and components, contributing to both aesthetic appeals and toughness

The customer items industry incorporates aluminum spreading in things like pots and pans and showing off devices, leveraging the product's stamina and rust resistance. On the whole, the convenience of aluminum spreading makes it a crucial process in conference diverse manufacturing needs throughout numerous fields.

The Refine of Aluminum Casting

Casting light weight aluminum entails several well-defined steps that change basic materials into finished elements. The procedure starts with melting light weight aluminum in a furnace, reaching temperatures around 660 degrees Celsius. When thawed, the liquid aluminum is poured into a mold and mildew, which takes the form of the wanted part. Various mold kinds, consisting of sand, irreversible, and financial investment mold and mildews, are made use of depending on the application.

After putting, the light weight aluminum strengthens and cools down, creating a harsh spreading. This casting goes through a collection of completing procedures, such as machining, to attain specific measurements and surface area quality. Quality assurance measures are implemented throughout to guarantee the integrity and toughness of the end product. As soon as all procedures are total, the finished light weight aluminum elements await various applications, showcasing the versatility and performance of light weight aluminum spreading in production techniques. Each step is vital in achieving top quality results, making this procedure crucial in producing markets.

Developments in Aluminum Spreading Innovation

Recent developments in aluminum spreading innovation have changed production processes substantially. Developments such as innovative casting methods, assimilation of wise manufacturing, and sustainability techniques are reshaping the sector. These advancements not only boost effectiveness yet likewise address environmental problems, paving the means for a much more sustainable future in light weight aluminum casting.Advanced Spreading Techniques

As manufacturers look for better effectiveness and sustainability in manufacturing, ingenious advancements in aluminum casting innovation have actually emerged to fulfill these demands. Advanced casting approaches, such as die casting, financial investment casting, and sand spreading, have been fine-tuned to boost precision and minimize waste. Die casting enables faster production prices and tighter tolerances, making it suitable for high-volume items. Financial investment spreading, known for its ability to produce intricate geometries, makes it possible for elaborate styles with superior surface coatings. On the other hand, sand spreading continues to be popular for its convenience and cost-effectiveness, particularly in low-volume applications. These techniques not only boost the top quality of aluminum components however likewise add to lowered energy consumption, aligning with market goals for lasting practices in manufacturing processes.Smart Production Integration

How can wise manufacturing combination transform aluminum casting innovation? By integrating innovative modern technologies such as the Net of Points (IoT), expert system (AI), and data analytics, clever production boosts performance and accuracy in light weight aluminum casting processes. Real-time monitoring of equipment and production lines allows for immediate changes, lowering waste and downtime. Anticipating upkeep powered by AI lessens equipment failures, guaranteeing constant quality. Additionally, information analytics can enhance casting styles and specifications, bring about far better material usage and decreased cycle times. These developments help with seamless interaction between operators and machines, cultivating a much more nimble manufacturing atmosphere. In general, smart production integration significantly elevates the capacities of aluminum spreading, advertising better outcomes and even more receptive manufacturing practices.Sustainability Innovations

While the aluminum spreading industry encounters enhancing pressure to take on sustainable techniques, developments are arising that noticeably decrease its environmental effect. Advanced recycling strategies now make it possible for producers to make use of as much as 95% recycled light weight aluminum, substantially lowering power consumption and waste generation. Additionally, the integration of low-emission innovations, such as electrical melting heating systems, decreases greenhouse gas emissions associated with standard casting techniques. In addition, the development of green coverings and binders replaces harmful chemicals, improving office safety and security and decreasing ecological pollution. These advancements not just align with worldwide sustainability objectives yet also improve the general effectiveness and top quality of aluminum items. As the sector advances, these developments will play a necessary duty in cultivating a more sustainable future for aluminum casting.Comparing Aluminum Casting With Other Techniques

In comparing aluminum casting with various other producing techniques, numerous essential factors arise. Price strength, efficiency and durability, and design flexibility work as vital metrics for examination (Precision aluminum casting). Assessing these facets can supply insights right into the advantages and constraints of aluminum spreading in various production contextsExpense Efficiency Analysis

Price efficiency remains an extremely important factor to consider in manufacturing procedures, especially when assessing light weight aluminum spreading against different methods. Light weight aluminum casting often provides a lower first investment contrasted to methods such as steel building or machining, which call for more elaborate and pricey equipment. In addition, aluminum's light-weight nature can lower transportation prices and energy intake during manufacturing. The capacity to produce intricate shapes with very little waste further improves its cost-effectiveness, as less product is discarded throughout the production procedure. Light weight aluminum casting normally permits for quicker production cycles, leading to minimized labor prices and faster turnaround times. To sum up, when contrasting cost efficiency, light weight aluminum spreading frequently emerges as a positive alternative, providing makers financial benefits along with top notch result.Strength and Sturdiness

Strength and longevity are crucial aspects when examining production approaches, particularly in the context of aluminum casting. Contrasted to other approaches such as plastic injection molding and steel fabrication, aluminum casting provides distinct advantages. The integral residential properties of light weight aluminum, incorporated with the spreading procedure, cause light-weight yet durable elements that can withstand substantial stress and anxiety and ecological variables. Unlike plastics, which might weaken with time, light weight aluminum keeps its stability and efficiency under high temperatures and pressures. Additionally, while steel parts can be larger and susceptible to rust, aluminum stands up to rusting, boosting durability. This combination of strength and resilience makes aluminum casting a preferred choice for industries calling for trusted efficiency popular applications, such as automobile and aerospace fields.Design Adaptability Comparison

The Future of Light Weight Aluminum Casting in Manufacturing

Just how will developments in modern technology shape the future of aluminum casting in production? The assimilation of automation and expert system is expected to reinvent light weight aluminum casting processes. These technologies can improve accuracy and efficiency, reducing waste and production expenses. In addition, the emergence of 3D printing methods permits for rapid prototyping and personalized styles, making it possible for manufacturers to respond quickly to market needs.Sustainability is additionally a crucial focus, with technologies intended at reducing energy usage and lessening ecological influence. Strategies such as die spreading and investment casting are evolving to incorporate recycled aluminum, promoting a circular economic climate.

Developments in materials science might lead to the growth of lighter, more powerful light weight aluminum alloys that might broaden the applications of aluminum casting throughout numerous markets. Generally, the future of aluminum casting in production will likely be identified by enhanced adaptability, performance, and sustainability, placing it as an essential part of modern manufacturing methods.

Frequently Asked Inquiries

Exactly How Does Aluminum Spreading Effect Environmental Sustainability?

Aluminum spreading favorably impacts ecological sustainability by promoting recycling, reducing power consumption contrasted to other steels, and reducing waste. Its light-weight homes also cause lower discharges during transportation, sustaining greener methods in various markets.What Are the Cost Ramifications of Aluminum Casting?

Light weight aluminum casting usually involves greater first expenses because of product and processing expenditures. Its longevity and lightweight properties can produce lasting financial savings by decreasing maintenance and transport prices, ultimately balancing the economic effects for manufacturers.Can Aluminum Spreading Be Recycled Properly?

Aluminum casting can be reused effectively, as the material maintains its buildings throughout the reusing procedure. This enables the manufacturing of high-quality components while reducing waste and minimizing power usage linked with new aluminum manufacturing.What Safety Measures Are Needed Throughout Light Weight Aluminum Spreading?

Safety and security procedures during aluminum casting consist of making use of individual safety devices like gloves and safety glasses, making sure correct air flow, preserving equipment, and following methods for dealing with liquified steel to protect against burns, breathing dangers, and other potential crashes.

How Does Aluminum Spreading Affect Item Style Versatility?

Aluminum casting Aluminum Casting Company enhances product design flexibility by making it possible for lightweight frameworks and complex shapes. This technique allows developers to check out ingenious configurations, resulting in versatile applications throughout numerous markets while preserving toughness and durability in the final items.Aluminum casting can be adjusted to various strategies, such as sand spreading or die spreading, which expands its applicability throughout industries. As soon as all processes are complete, the completed light weight aluminum elements are all set for different applications, showcasing the adaptability and efficiency of light weight aluminum casting in production methods. As producers look for higher effectiveness and sustainability in production, innovative innovations in aluminum spreading innovation have actually emerged to fulfill these demands. Unlike plastic injection molding, which may need comprehensive tooling changes for style adjustments, aluminum spreading can accommodate adjustments more conveniently during the manufacturing cycle. Advancements in materials scientific research might lead to the advancement of lighter, more powerful light weight aluminum alloys that might broaden the applications of aluminum spreading throughout different sectors.

Report this wiki page